THE MATRIX-POTTING MACHINE

THE MATRIX-POTTING MACHINE

BREAK THE CIRCLE - GO LINEAR

BREAK THE CIRCLE - GO LINEAR

Find out all you need to know about the patented MATRIX potting machine and its cutting-edge innovations that will inspire you!

Find out all you need to know about the patented MATRIX potting machine and its cutting-edge innovations that will inspire you!

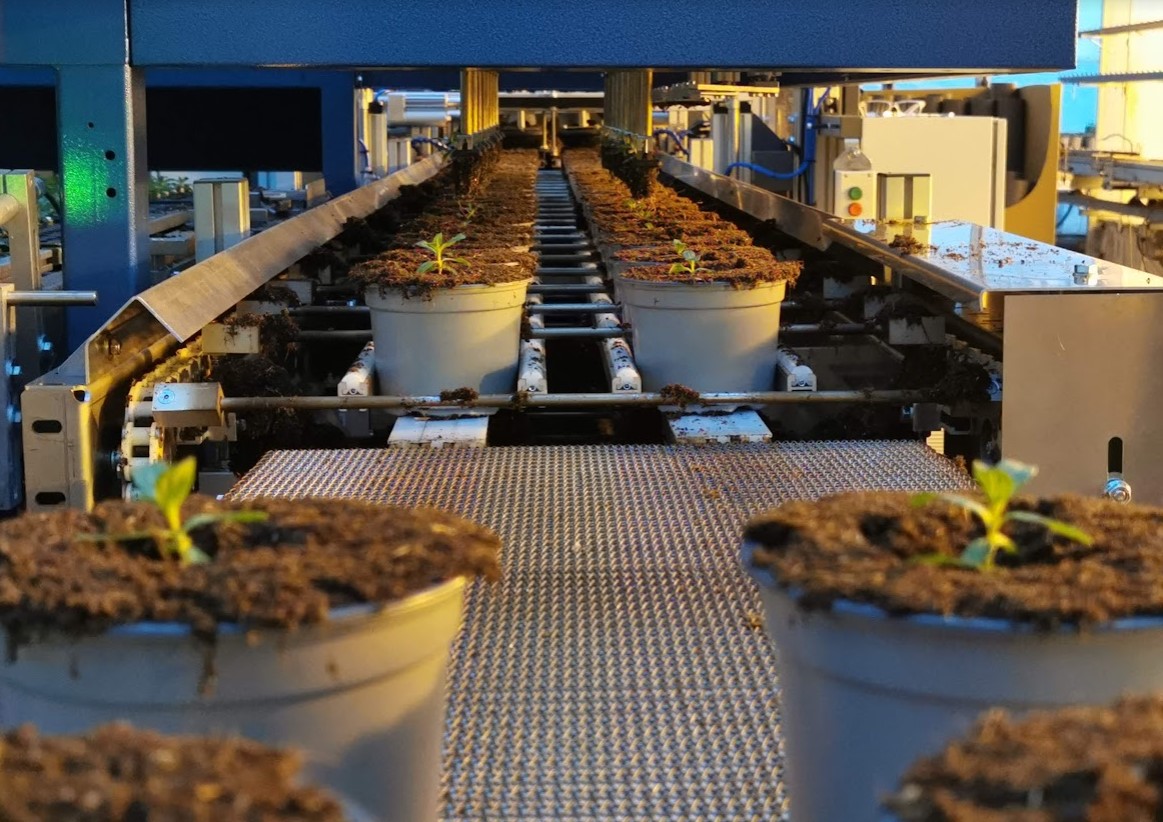

The patented MATRIX linear potting machine is available in several versions: as the MATRIX T2.4, T2.2 COMPACT, T2.2, and MATRIX T1.1. Each of these variants has been designed for specific application areas and is equipped with different performance levels. The tray filling machine is available as the TY model series, which is technically based on the platform of potting machines but differs in some characteristics.

As a linear potting machine, the MATRIX revolutionizes the conventional concept of potting machines with rotating ring or chain drive. Its computer-controlled technology, the design featuring decoupled drives, and the patented machine concept enable it to effortlessly achieve impressive performance figures of up to 10,000 pots per hour*.

A potting machine that could also be called a potting robot: The MATRIX is a potting machine that deliberately breaks new ground. It is very different from conventional potting machines. The MATRIX is computer controlled and has an impressive output of up to 10,000* pots per hour.

1. THE POTTING CELL

1. THE POT CELL

The compact potting cell in solid welded construction forms the basis of the inner workings of every MATRIX potting machine.

This makes the MATRIX a compact machine in relation to its output, taking up little space in your plant.

In addition, the MATRIX potting cell covers the entire working area and serves as a stable transport mechanism.

Other parts of the MATRIX are made from high quality aluminium, and some key components are even made from Gr5 Ti6Al4V titanium, which is also used in aerospace applications.

The compact potting cell in solid welded construction forms the basis of the inner workings of every MATRIX potting machine.

This makes the MATRIX a compact machine in relation to its output, taking up little space in your plant.

In addition, the MATRIX potting cell covers the entire working area and serves as a stable transport mechanism.

Other parts of the MATRIX are made from high quality aluminium, and some key components are even made from Gr5 Ti6Al4V titanium, which is also used in aerospace applications.

2. INNOVATIVE ELEVATOR

2. INNOVATIVE ELEVATOR

The innovative elevator of the MATRIX potting machine is arranged crosswise to the soil hopper. It offers the following advantages:

The innovative elevator of the MATRIX potting machine is arranged crosswise to the soil container. It offers the following advantages:

-

For the first time in a potting machine, a precisely measurable and controllable supply of soil to the pots is guaranteed.

-

The substrate is no longer pushed directly onto the elevator blades, reducing the load on the drive chain. The elevator only pulls as much substrate as is needed.

-

Easy maintenance: Elevator, drive chains and elevator blades are easily accessible through doors. Blades can be changed in no time at all - without having to climb into the machine.

-

For the first time in a potting machine, a precisely measurable and controllable supply of soil to the pots is guaranteed.

-

The substrate is no longer pushed directly onto the elevator blades, reducing the load on the drive chain. The elevator only pulls as much substrate as is needed.

-

Easy maintenance: Elevator, drive chains and elevator blades are easily accessible through doors. Blades can be changed in no time at all - without having to climb into the machine.

Another new feature is that both the soil hopper drive and the elevator drive are frequency and computer controlled.

Another new feature is that both the soil container drive and the elevator drive are frequency and computer controlled.

3. PLC CONTROL

3. PLC CONTROL

WITH A 10.1-INCH TOUCHSCREEN UNIT

WITH A 10.1-INCH TOUCHSCREEN UNIT

A bright 10.1" touch screen allows you to easily recall stored workflows with different filling and drilling sequences - even during operation!

Thanks to the computer control, the MATRIX offers an almost infinite number of process settings, making it highly customisable and convenient to use.

A bright 10.1" touch screen allows you to easily recall stored workflows with different filling and drilling sequences - even during operation!

Thanks to the computer control, the MATRIX offers an almost infinite number of process settings, making it highly customisable and convenient to use.

4. POT MAGAZINE

4. POT MAGAZINE

ELECTRIC HEIGHT ADJUSTMENT & POT SIZE CHANGE IN SECONDS

ELECTRIC HEIGHT ADJUSTMENT & POT SIZE CHANGE IN SECONDS

The robust pot magazine of the MATRIX potting machine is pneumatically driven, equipped with double jaws and electrically height adjustable at the touch of a button as standard.

With the MATRIX Easy-Switch system, changing pot sizes is faster than ever! In just a few steps, the pot magazine can be changed from one pot to another in seconds!

The robust pot magazine of the MATRIX potting machine is pneumatically driven, equipped with double jaws and electrically height adjustable at the touch of a button as standard.

With the MATRIX Easy-Switch system, changing pot sizes is faster than ever! In just a few steps, the pot magazine can be changed from one pot to another in seconds!

5. LINEAR POT TRACK

5. LINEAR POT TRACK

LINEARITY AS AN ADVANTAGE

LINEARITY AS AN ADVANTAGE

The MATRIX is a linear potting machine, i.e. the side guides are always parallel. This has the following advantages

The MATRIX is a linear potting machine, i.e. the side guides are always parallel. This has the following advantages

-

As standard, the side guides can be easily and conveniently adjusted to the pot size in use at the touch of a button. The side guides can be changed to suit other pot sizes in a matter of seconds.

-

Perfect for use in combination with a planting robot. Benefits include increased system performance and even wear and tear on the robot arms**.

-

Easy to service and maintain: The complete potting line including the pot tracks can be removed from the machine on castors if required.

-

As standard, the side guides can be easily and conveniently adjusted to the pot size in use at the touch of a button. The side guides can be changed to suit other pot sizes in a matter of seconds.

-

Perfect for use in combination with a planting robot. Benefits include increased system performance and even wear and tear on the robot arms**.

-

Easy to service and maintain: The complete potting line including the pot tracks can be removed from the machine on castors if required.

6. POT CARRIERS

6. POT CARRIERS

AUTOMATIC ADJUSTMENT & CENTRAL DRILLING

AUTOMATIC ADJUSTMENT & CENTRAL DRILLING

Unlike side guides, which can be adjusted at the touch of a button, the pot drivers on the MATRIX automatically adjust to the pot size being used once the programme has been selected.

This means that drilling is always centred. Manual adjustment of the cup drivers is no longer necessary.

Unlike side guides, which can be adjusted at the touch of a button, the pot drivers on the MATRIX automatically adjust to the pot size being used once the programme has been selected.

This means that drilling is always centred. Manual adjustment of the cup drivers is no longer necessary.

7. INTELLIGENT DRILLING PROGRAMS

7. INTELLIGENT DRILLING PROGRAMS

WITH CRASH-STOP FEATURE

WITH CRASH-STOP FEATURE

Each individual drill on the MATRIX potting machine has its own drill motor with gear reduction, which increases the torque enormously.

For the first time on a potting machine, the following parameters can be set as required: drilling speed, drilling direction (right, left), drilling pattern (single/double/compact) and the stroke speed of the drilling gantry. The drilling function can be deactivated at the touch of a button - even during operation - when drilling is not required.

Our Crash-Stop feature ensures that drilling is always centred and never too deep. Incorrect operation is therefore impossible.

Each individual drill on the MATRIX potting machine has its own drill motor with gear reduction, which increases the torque enormously.

For the first time on a potting machine, the following parameters can be set as required: drilling speed, drilling direction (right, left), drilling pattern (single/double/compact) and the stroke speed of the drilling gantry. The drilling function can be deactivated at the touch of a button - even during operation - when drilling is not required.

Our Crash-Stop feature ensures that drilling is always centred and never too deep. Incorrect operation is therefore impossible.

8. UNCOMPROMISING WORK SAFETY

8. UNCOMPROMISING WORK SAFETY

The safety concept of the MATRIX potting machine meets all international standards for occupational safety: In addition to large emergency stop switches, access doors protected by circuit breakers cover the entire working area of the MATRIX.

This not only allows easy access, but also ensures safe working on the machine.

The safety concept of the MATRIX potting machine meets all international standards for occupational safety: In addition to large emergency stop switches, access doors protected by circuit breakers cover the entire working area of the MATRIX.

This not only allows easy access, but also ensures safe working on the machine.

-

The MATRIX potting machine can be configured with one track or, as an option, with two parallel tracks.

-

The MATRIX potting machine can be equipped with 2 or optionally 4 drills. This allows 2 or 4 pots to be drilled per cycle.

-

The MATRIX potting machine can be configured with one track or, as an option, with two parallel tracks.

-

The MATRIX potting machine can be equipped with 2 or optionally 4 drills. This allows 2 or 4 pots to be drilled per cycle.

OTHER SPECIAL FEATURES

OTHER SPECIAL FEATURES

SERVICE FRIENDLY

SERVICE FRIENDLY

REDUCED MAINTENANCE COSTS

REDUCED MAINTENANCE COSTS

The MATRIX is designed for easy access and maintenance. Ergonomically designed guards are easy to remove and make work much easier. A further special feature of the MATRIX: For maintenance and repair work, the complete potting line can be pulled out of the machine.

The MATRIX is designed for easy access and maintenance. Ergonomically designed guards are easy to remove and make work much easier. A further special feature of the MATRIX: For maintenance and repair work, the complete potting line can be pulled out of the machine.

INDIVIDUALITY

INDIVIDUALITY

UPGRADE-POSSIBILITIES

UPGRADE-POSSIBILITIES

All MATRIX machines are compatible with each other and can be retrofitted to other MATRIX models at the factory. This makes it easier and less expensive to increase output or change the potting area of the machine than to purchase a completely new machine.

All MATRIX machines are compatible with each other and can be retrofitted to other MATRIX models at the factory. This makes it easier and less expensive to increase output or change the potting area of the machine than to purchase a completely new machine.

* The performance figures given will always depend on the type of substrate used and the size of the pot.

** Whereas the outer and inner arms of a planting robot working with a rotary potting machine have to travel different distances, the arms of a planting robot working with a MATRIX potting machine always travel the same distance.